A family run North Devon based CNC machining company offering the following services UK wide:

– Wire & Spark Erosion

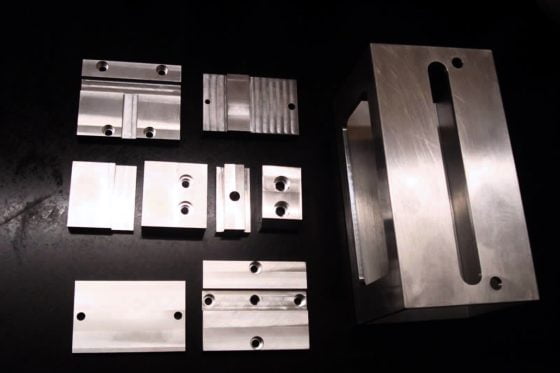

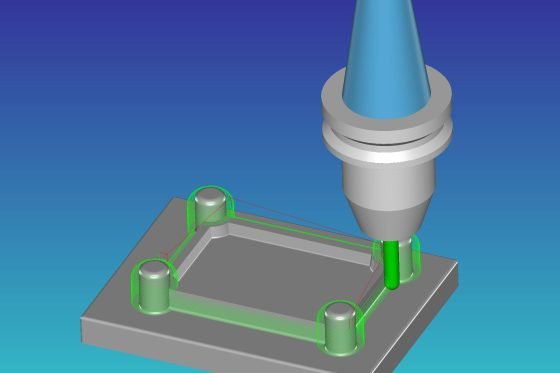

– CNC Milling & Turning

– Surface Grinding

– Precision Toolmaking

D K Precision offer a fast turnaround service on parts needed quickly. We offer over 25 years experience in precision engineering excellence.

As a small company our specialist area is in the manufacture of quality prototype parts and small to medium batch runs.

Machining Capabilities

Plastic injection mould tools and progression press tool can be made from product drawing. Replacement punches or inserts can also be supplied for existing tools or recut.

Testimonial

” I have dealt with D K Precision over the last 15 years and have been entirely satisfied with their service , superb quality , and attention to detail in producing various components for my company such as mould and press tools parts.

They have always delivered on time and with very good prices. ”

( David Pugh , DGPugh Toolmaker Ilfracombe North Devon )